Weaver NDT is a Certified Service Disabled Veteran Owned Small Business

Our Approach

Reliable, Repeatable, Quality Non Destructive Testing

The one-size-fits-all approach will never help your NDT and/or Quality departments reach their full potential. We deliver custom non destructive testing systems and solutions, tailored to your industry, your culture, your one-of-a-kind challenges.

We can focus on your entire NDT and Quality program or only on specific areas of interest where detailed review and recommended improvements will benefit you the most.

An experienced and certified set of eyes can always help in adding value to your non destructive testing processes.

Learn More

EXPERT ANALYSIS

Expert review of resonance data, radiographs, and computed tomography data

STRATEGIC TECHNIQUES

Ensuring that you are compliant and flexible

RISK MANAGEMENT

Minimizing your risks along the way

Experience

Additional Information

Inspection personnel are company certified to Levels I & II in various non destructive testing (NDT) methods and have quality auditing experience.

The Responsible Level III, Greg Weaver, is NAS-410 and ASNT Level III (#149144) certified in Radiographic and Liquid Penetrant Testing as well as NAS-410 certified in Ultrasonic Testing. Greg also holds company NAS-410 Level II certifications in Electromagnetic Inspection and Resonance Inspection.

He has extensive experience with many manufacturing methodologies that include:

- Casting (including Single Crystal)

- Additive Manufacturing

- Machining

- Composite Matrix Ceramics

- and many more areas

Auditing experience is hands-on and derived from over 25 years of Quality background. Positions previously held are Vice President, Senior Quality Manager at an FAA 145 Repair Station, Quality Manager, Responsible Level III, External and Internal Auditor, FAA Repairman, and Designated Manufacturing Inspection Repairman.

Publications

Computed Tomography for NDT

Competent, Qualified and Certified

Computed Tomography for NDT

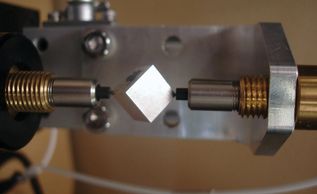

X-ray Diffraction

Competent, Qualified and Certified

Computed Tomography for NDT

Competent, Qualified and Certified

Competent, Qualified and Certified

Additive Manufacturing and the Inspection Process

Additive Manufacturing and the Inspection Process

Additive Manufacturing and the Inspection Process

NDT Data for Process Control and Monitoring

NDT Data for Process Control and Monitoring

NDT Flaw Detection 101

Additive Manufacturing and Inspection Difficulties

Additive Manufacturing and Inspection Difficulties

Additive Manufacturing and Inspection Difficulties

Additive Manufacturing and Inspection Difficulties

Additive Manufacturing and Inspection Difficulties

Resonance Testing for Material Analysis

Additive Manufacturing and Inspection Difficulties

Resonance Testing for Material Analysis

Aerospace NDT ASNT Industry Handbook

Holographic Pseudo-Free Vibration Analysis

Resonance Testing for Material Analysis

Resonance Testing Provides Results

Holographic Pseudo-Free Vibration Analysis

Holographic Pseudo-Free Vibration Analysis

Holographic Pseudo-Free Vibration Analysis

Holographic Pseudo-Free Vibration Analysis

Holographic Pseudo-Free Vibration Analysis

Photo Gallery

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.